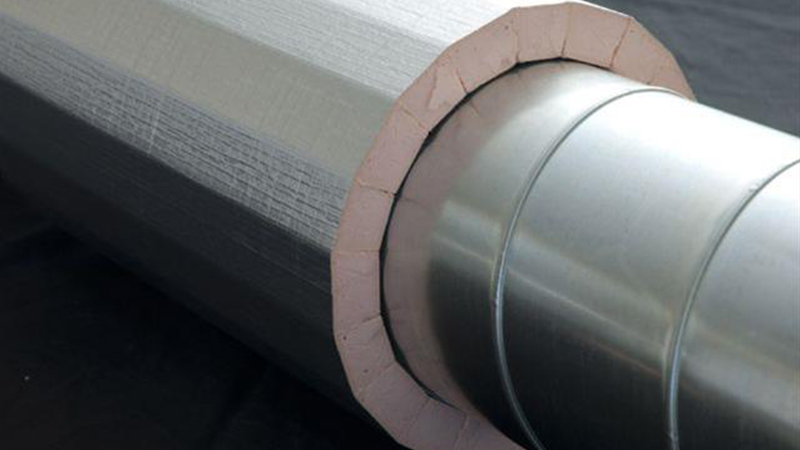

PHENOLIC FOAM PIPE & DUCT INSULATION

Phenolic Foam Pipe & Duct Insulation

Phenolic Foam is a rigid cellular foam insulation material with a substantially closed cell structure, whose polymer structure is made primarily from poly-condensation of phenol, its homologues and/or derivatives with aldehydes and ketones.

Phenolic foam has various distinct properties that makes it better than conventional insulation materials.

Lower K Value (K Value = 0.018W/mk) – that means exceptionally low thermal conductivity.

Main application: Phenolic Foam are used for the application of Chilled Water Pipe and Duct Insulation.

Wide service range for diverse insulation.

Cost-effective due to lower thermal conductivity facilitates usage of lesser thickness of Phenolic Foam for the same level of insulation.

A wide service temperature range between -196°C to +130°C makes Phenolic Foam ideal for low temperature and cryogenic applications. It can be effectively used on LSHS, fuel oil, low pressure steam and hot water lines.

Low water absorption is a key feature of Phenolic Foam. A high closed cell content of up to 95% results in very low water vapour transmission and reduces condensation.

Phenolic Foam assures longer life as it is unaffected by most aromatic and aliphatic solvents. Odorless and does not absorb colour.

Rodent/insect proof and being mildly antiseptic resists fungal and bacterial growth.

Corrosion and chemical resistance is another strength. Isoline Phenolic Foam resists organic solvents and chemicals. Being non-abrasive and hydrophobic, it does not corrode metal.

Phenolic Foam has anti-static properties. It is an electrical insulator and in case of friction does not generate static electricity of sparks.

Phenolic Foam is workable, easy to install and can be cut and shaped to any size with hand tools.

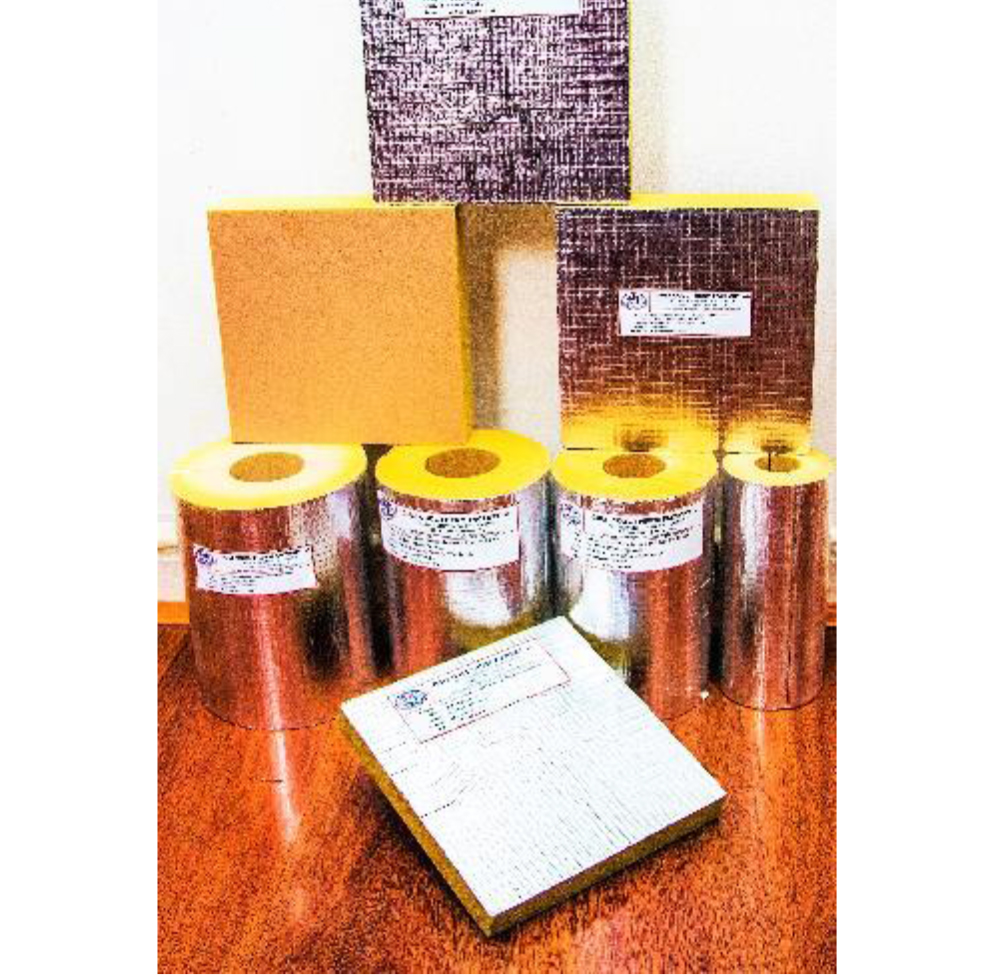

Availability pipe sections, faced with reinforced Aluminum foil(Class'1') or (Class 'O') or un-faced.

Pipe fittings include Elbows, Tees, Valve, Covers, etc.

Pipe Supports faced with reinforced Aluminum foil or un-faced.

Duct Board faced with one side reinforced Aluminum foil (Class '1') or (Class 'O') or un-faced.

Density 35Kg/m3 to 50Kg/m3 for pipe sections and slabs. 65Kg/m3 to 120Kg/m3 for the use of Thermal Supports.

Diverse Applications:

© 2017 Gulf Cool Therm Factory LTD - Powered By WEB DESIGN DUBAI